Understanding your gas meter is crucial for ensuring safety and efficient energy use. A malfunctioning meter can lead to inaccurate billing, gas leaks, or even dangerous situations. This guide provides four practical methods to diagnose potential problems with your gas meter, empowering you to take proactive steps to maintain a safe and functional home energy system. We’ll explore visual inspections, analyzing meter readings, detecting leaks, and understanding the nuances of different gas types.

By carefully examining your gas meter and understanding its behavior, you can identify issues early on, preventing potential problems and ensuring your home remains safe and energy-efficient. This approach promotes both safety and informed energy management.

Visual Inspection of the Gas Meter

A visual inspection is often the first step in troubleshooting gas meter issues. By carefully examining the meter’s components, you can identify potential problems before they escalate. This process requires caution and adherence to safety protocols to prevent accidents.

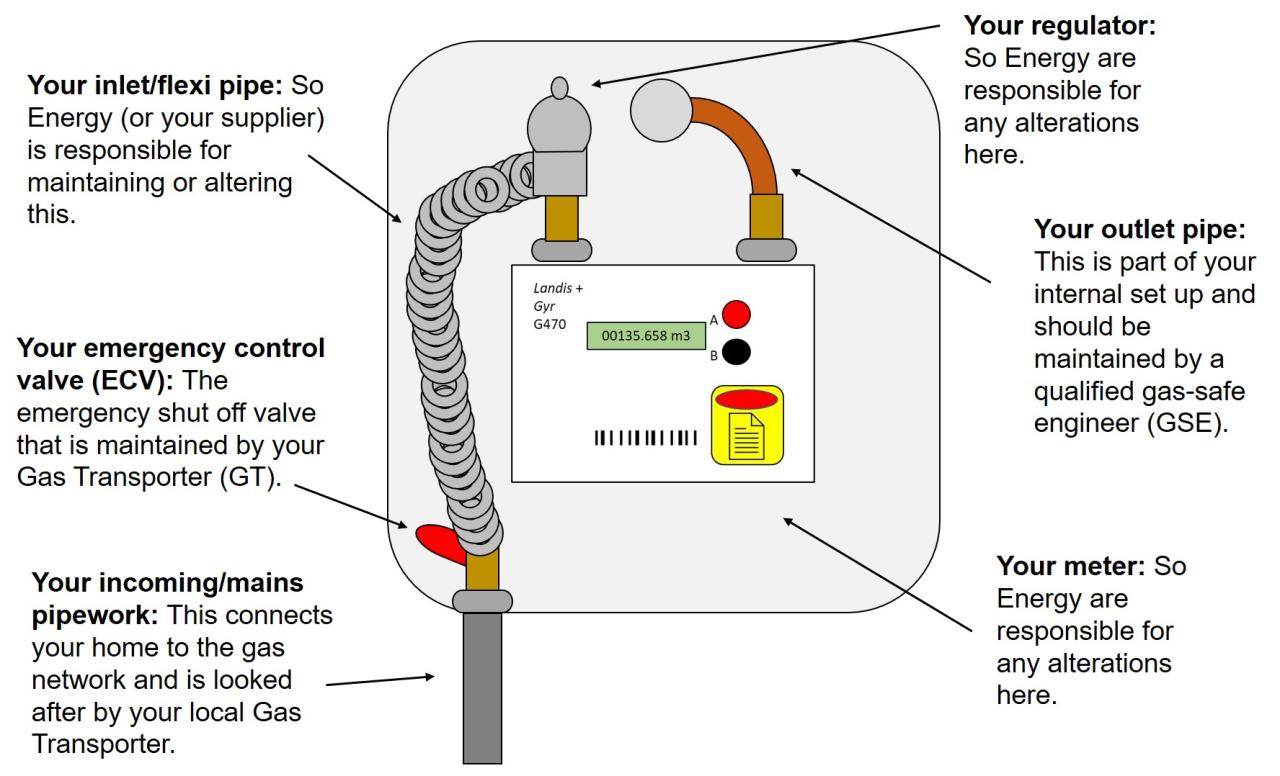

Gas Meter Components and Their Functions

Understanding the different parts of your gas meter is crucial for effective inspection. The following table details typical components, their functions, how to inspect them, and potential issues to watch for.

| Component | Function | Inspection Method | Potential Issues |

|---|---|---|---|

| Dial/Display | Shows gas consumption. | Check for clarity, correct readings, and unusual markings. | Cracked glass, inaccurate readings, stuck needle. |

| Meter Body | Houses internal mechanisms. | Inspect for dents, rust, corrosion, or damage. | Significant damage compromising integrity, signs of leakage. |

| Gas Inlet/Outlet Pipes | Connects the meter to the gas supply and appliance. | Check for cracks, leaks, loose connections, or corrosion. | Leaks, loose fittings, rust, damage to pipework. |

| Seals/Gaskets | Prevent gas leaks. | Visually inspect for damage or deterioration. | Cracks, missing seals, signs of leakage around connections. |

| Pressure Regulator (if present) | Regulates gas pressure. | Check for any visible damage or unusual wear. | Leaks, malfunction, unusual noises. |

Types of Gas Meters and Their Visual Characteristics

Gas meters vary in design depending on the type of gas and the metering technology used. This table highlights some common differences and potential failure points.

| Meter Type | Visual Characteristics | Potential Failure Points |

|---|---|---|

| Rotary Meter (common in residential settings) | Typically has a rotating dial or multiple dials showing gas usage. Often a cylindrical or rectangular metal casing. | Worn gears, damaged internal mechanisms, leaks around seals. |

| Diaphragm Meter (used for lower pressure applications) | Usually has a more complex internal structure, less visible moving parts than rotary meters. | Diaphragm failure, leakage from internal seals, worn components. |

| Electronic Meter (increasingly common) | Often features a digital display showing gas usage, smaller in size and may have fewer visible moving parts than mechanical meters. | Electronic component failure, communication issues, inaccurate readings. |

Safety Precautions for Gas Meter Inspection

Safety is paramount when inspecting a gas meter. Never attempt an inspection if you are unsure or uncomfortable. Always follow these safety precautions:

| Safety Measure | Description |

|---|---|

| Turn off appliances | Before beginning the inspection, turn off all gas appliances connected to the meter. |

| Ventilate the area | Ensure adequate ventilation to prevent gas buildup. |

| Check for leaks (using soapy water) | Apply soapy water to connections; bubbles indicate a leak. If a leak is suspected, immediately contact your gas supplier. |

| Avoid open flames | Do not use open flames or sparks near the meter. |

| Contact your gas supplier | If you find any damage or suspect a leak, contact your gas supplier immediately. Do not attempt repairs yourself. |

| Wear appropriate PPE | Consider wearing gloves to protect your hands. |

Checking for Unusual Readings or Meter Behavior

Accurately reading your gas meter is crucial for identifying potential problems. Understanding how your meter functions and recognizing deviations from normal behavior can help you detect issues early, preventing costly repairs or safety hazards. This section will guide you through interpreting your meter readings and recognizing signs of malfunction.

Interpreting Gas Meter Readings and Identifying Unusual Consumption

Gas meters typically display your gas consumption in cubic feet (cf) or cubic meters (m³). Older meters may use dials, while newer ones often feature digital displays. For dial meters, read the numbers from left to right, noting the position of each dial’s pointer. For digital meters, the reading is directly displayed. To determine your gas usage, compare consecutive readings taken over a specific period (e.g., monthly). A significantly higher or lower consumption than your usual pattern warrants further investigation. For instance, a sudden jump from an average monthly consumption of 500 cf to 1500 cf could indicate a leak or appliance malfunction. Conversely, a consistently low reading compared to your typical usage might suggest a blockage in the gas line. Keep records of your monthly readings to establish a baseline for comparison.

Erratic Readings, Constantly Running Meter, or No Reading at All

A malfunctioning gas meter can manifest in several ways. Erratic readings, characterized by fluctuating numbers or inconsistent increases, suggest a problem with the meter’s internal mechanisms. For example, the pointer on a dial meter might jump erratically between numbers, or a digital meter might display rapidly changing figures. A constantly running meter, even when no gas appliances are in use, is a serious issue indicating a possible gas leak or internal meter malfunction requiring immediate attention. This scenario presents a clear safety risk and necessitates immediate action. Conversely, a meter showing no reading at all implies a complete failure of the meter’s recording mechanism or a problem with the gas supply itself. This necessitates immediate contact with your gas provider.

Comparison of Normal and Problematic Gas Meter Behavior

Understanding the difference between normal and problematic meter behavior is vital for early detection of issues.

- Normal Gas Meter Behavior: Readings increase steadily, reflecting typical gas usage patterns. The meter operates smoothly and quietly. Readings are consistent and easily interpretable.

- Problematic Gas Meter Behavior: Readings fluctuate erratically, showing inconsistent increases or decreases. The meter may run continuously, even when no gas appliances are in use. The meter may display no reading at all. Unusual sounds (hissing, clicking) may emanate from the meter.

Identifying Leaks and Odors

Detecting gas leaks is crucial for safety. Natural gas, while odorless in its pure form, is treated with a strong-smelling additive (usually mercaptan) to alert users to potential leaks. Propane, on the other hand, has a distinct odor even without additives. Recognizing these smells and employing appropriate detection methods can prevent serious accidents.

Identifying gas leaks involves a combination of visual inspection and specialized techniques. A visual inspection should check for any visible damage to gas lines, fittings, or appliances. This includes looking for cracks, corrosion, or loose connections. However, many leaks are invisible to the naked eye, necessitating further investigation.

Detecting Gas Leaks with Soapy Water

The soapy water test is a simple yet effective method for detecting gas leaks. Mix a solution of dish soap and water in a spray bottle. Lightly spray the solution around suspected leak points, such as gas pipe joints, appliance connections, and meter seals. If a leak is present, the escaping gas will form bubbles in the soapy water, clearly indicating the leak’s location. The size and rate of bubble formation can give an indication of the leak’s severity. For example, rapid and large bubble formation would suggest a significant leak requiring immediate action. Conversely, small, slow bubbles might indicate a minor leak that requires attention but may not pose an immediate threat. Always exercise caution when conducting this test, ensuring proper ventilation and avoiding open flames or sparks.

Safety Hazards Associated with Gas Leaks

Gas leaks pose several significant safety hazards. The most immediate danger is the risk of explosion or fire. Accumulated gas can ignite if it comes into contact with an ignition source, such as a pilot light, electrical spark, or even a static discharge. In addition to explosions and fires, gas leaks can also lead to asphyxiation. Natural gas displaces oxygen in the air, leading to oxygen deprivation, which can be fatal. Furthermore, prolonged exposure to high concentrations of natural gas can cause headaches, nausea, dizziness, and other health problems.

In the event of a suspected gas leak, it’s crucial to act quickly and decisively. First, evacuate the building immediately and move to a safe distance. Then, call your gas company’s emergency number or your local emergency services. Avoid using electrical appliances or creating any sparks or flames. Do not attempt to repair the leak yourself. Allow the gas company’s trained professionals to handle the situation.

Types of Gas and Their Odors

Natural gas and propane are the most commonly used fuels for residential and commercial purposes. Natural gas is typically odorless in its pure form but is treated with a strong-smelling mercaptan to make leaks easily detectable. This added odor is usually described as a rotten egg smell. Propane, on the other hand, naturally possesses a distinct odor, often described as being slightly sweet or sulfurous. While the odor additive in natural gas serves as a warning, it is important to remember that the odor may not always be present, especially if the gas has been diluted or if the additive has degraded over time. Both gases are flammable and pose a risk of explosion and fire if they leak and accumulate in confined spaces. Propane, being heavier than air, can collect in low-lying areas, increasing the risk of accumulation and potential hazards.

Last Recap

Diagnosing gas meter issues effectively combines careful observation with safety precautions. By following the methods Artikeld – visual inspection, checking readings, leak detection, and understanding gas types – you can gain confidence in identifying and addressing potential problems. Remember to prioritize safety and contact a qualified professional if you encounter any uncertainty or suspect a significant issue. Proactive monitoring of your gas meter is key to ensuring a safe and efficient home environment.